Business

Company endeavoring to satisfy customers with

the continuous technology development and facility investment

ceramic powder

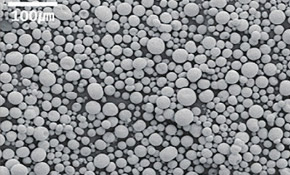

SW-YT35

| Purity (%) |

Particle Size (㎛) |

Flow-ability (g/s) |

Apparent density (g/㎤) |

Applications |

| 99.99 |

-53 ~ 10 |

3.0 |

2.1 |

LCD, Semiconductor, etc |

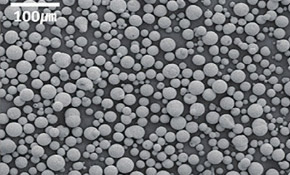

SW-YT25

| Purity (%) |

Particle Size (㎛) |

Flow-ability (g/s) |

Apparent density (g/㎤) |

Applications |

| 99.99 |

-35 ~ 5 |

3.0 |

2.1 |

Semiconductor, etc |

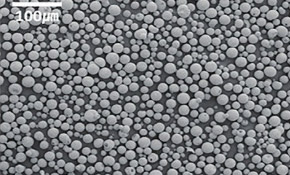

SW-YT20

| Purity (%) |

Particle Size (㎛) |

Flow-ability (g/s) |

Apparent density (g/㎤) |

Applications |

| 99.99 |

-20 ~ 5 |

3.5 |

1.9 |

Next generation Semiconductor |

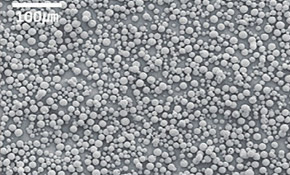

SW-YT15

| Purity (%) |

Particle Size (㎛) |

Flow-ability (g/s) |

Apparent density (g/㎤) |

Applications |

| 99.99 |

-20 ~ 5 |

1.4 |

1.3 |

Next generation Semiconductor |

thermal spray powder Y2O3

-

The yttria has excellent etching resistance and corrosion resistance in the environment of gas plasma including expecially halogen, and shows excellent electric insulation (volume resistivity and dielectric breakdown strength).

-

The high-purity yttria coating, which is used in the inside wall of chamber in the production process of semiconductor and display, is generally used as air plasma spray, and has excellent durability against etching and erosion in the NF3 Gas and CF3 Gas environment.

-

The denser the coating film is, the more excellent the etching resistance and insulation of plasm become. The fluidification technology of Sewon YT-25 powder can realize this feature. It is a specialized powder which can show the dense performance in the middle of the existing APS and SPS of coating film.