Display, SEMI Field

Parts coatings used for Plasma Chamber during semiconductor, OLED and Solar Cell processes can improve yields and productivity, such as stability of Particle and atmosphere and extension of part life.

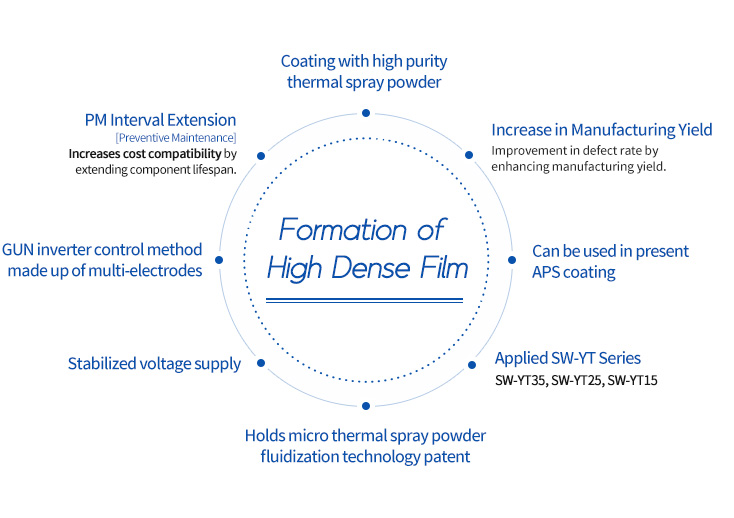

Development of high dense film Y2O3, Al2O3, YAG, YOF

We laminate the yttria very densely by using the multiple electrode plasma.coating applying the high-purity thermal spray powder

extension of PM cycle

It can increase the cost competitiveness by extending lifespan of partsStabilization of voltage supply

Possible to apply to the existing APS coating

Improvement of production yield

It can improve the defective percent by increasing the production yieldStable voltage supply through stable output of multiple electrode and rectification method of inverter

Patent on fluidification technology of minute thermal spray powder

SW-YT35

SW-YT25

SW-YT15

Diagram

Parts List