Powder Spray

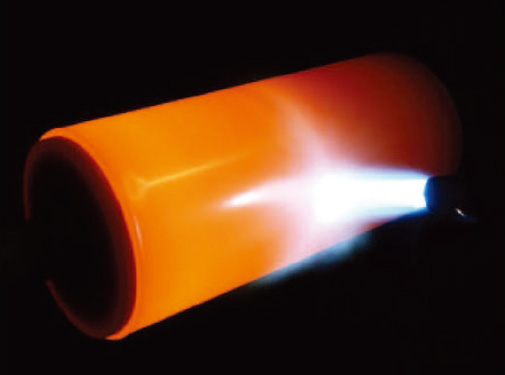

With oxygen + fuel gas as the heat source, this is the coating method of powder shaped thermal spray materials. For fuel gas, mainly used acetylene and hydrogen, propylene and profane accompanied by equipment. It is mainly sprayed Self-Fluxing Powder and improved its durability by increasing density and hardness of tissues through Fusing Process.coating image

powder spray

| Material No | Ingredients (%) | Characteristics | Example of application |

|---|---|---|---|

| 16C | Ni-16%Cr-4%Si-4%B-3%Cu-3%Mo-2.5%Fe-0.5%C | The coated surface is dense and strong against corrosion and abrasio. It is strong against thermal impact. | Piston ring, sleeve, none-magnetic parts/ |

| 31C | Ni-35%WC-11%Cr-2.5%Fe-2.5%Si-2.5%B-0.5%C | Display outstanding effect for erosion resistance, wear resistance and corrosion resistance after fusing. | Pump seal, cam follower, lock arm, capstan, cone, sleeve |

| 34F | WC-33%Ni-9%Cr-3.5%Fe-2%Si-2%B-0.5%C | The tissue is dense with outstanding wear resistance. It is strong against erosion by the particle. | Piston ring, sleeve, pump seal |