Wire Metalizing

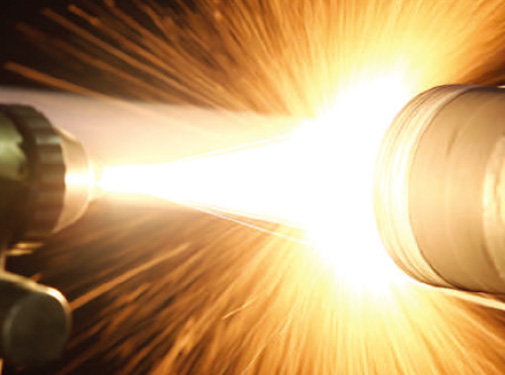

This is the coating method to form the film by the continuous thermal spray for various metals and alloys through combustion of acetylene + Oxygen(3100℃) and Propane + Oxygen(2700℃). If it is new part, it is improved its capacity, or if it is abrasive or corrosive, it is created its capacity like a new product by the cheap cost. As a result, it can be applied to widely industrial areas.coating image

wire metallizing

| Material No | Characteristics | Example of application |

|---|---|---|

| 99.9%Zn | Corrosion resistance | Wind power generation |

| 99%Al | It is strong against the erosion in atmosphere and has outstanding electric and thermal conductivity. | Non-magnetic parts, Electric conduction parts, semiconductor parts |

| 99%Cu | Outstanding thermal conductivity and electric conduction | Printing machine parts, Electre oonduction parts, Thermai-conductivity parts |

| 99%Mo | Outstanding wear resistance and lubrication | Engine block, Synchronizing ring, Paper roll |

| 95%Ni | Outstanding wear resistance development | Machine improvement and repairing |

| Co-25.5%Cr-10.5%Ni- 7.5%W-0.5%C | Outstanding wear resistance at high temperature and outstanding corrosion resistance and wear resistance | Boiler tube, Gas turbine |