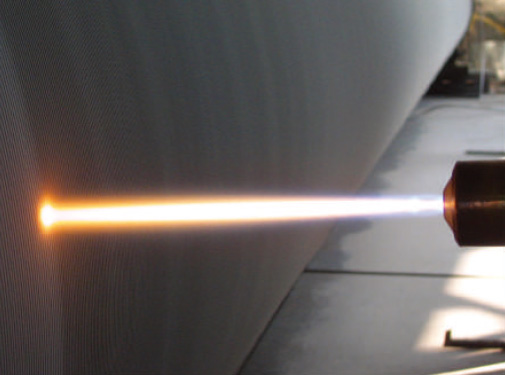

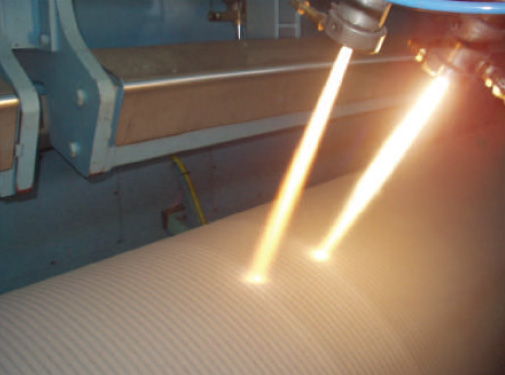

H.V.O.F Coating

This is a new spraying method to use the added heat and accelerate energy of jet flow(Speed: 2100 m/sec or more) of ultra speed extracted in high pressure condition (combustion pressure: 13 Bar) from the rocket combustion room to make the softening and accelerating for thermal spray materials by the maximum collision motion energy in a way of forming the extremely high close density film. For the thermal spray materials, there are metals with low fusion point, non-metal, ultra light alloy, metal carbides(WC), boron hydrides, and the flight speed of the thermal spray materials is extremely fast (Speed: 900m/sec or faster) that the staying time in the air is short, resulting in almost no change of property (oxidation and deformation), and it enables to obtain the ultra light film (W.C.: DPH 300 1400) of strong tissue with the finite density.coating image

h.v.o.f coating

| Material No | Ingredients (%) | Characteristics | Example of application |

|---|---|---|---|

| 81 | Cr3C2 Balance Ni20 Cr5 | Outstanding on oorrosion resistance, erosion resistance, and wear resistance with great lubrication, and strong for corrosion by the gas at high temperature. | Fuel rod, Pump housing Valve spindle |

| 71 | WC 88 CO 12 | The coating surface is dense and the wear resistance is outstanding on the friction surface. | Paper roll, Machine parts Pump sleeve, Fan blade Power generation facilities |

| 73 | WC 83 CO 17 | Outstanding against impact and wear resistance on the friction surface. | Gas turbine, Engine blade fan, Piston rod, Flanger Aircratt parts |